Why UV Roll Printers Are Ideal for Long-Run Printing

Discover how UV Roll Printers optimize efficiency, quality, and cost-effectiveness for large-scale printing jobs.

In the modern printing industry, efficiency and quality are critical when it comes to large-scale production. UV roll printers have quickly become a go-to choice for companies needing to manage long-run printing jobs. These printers stand out in their ability to produce consistent, high-quality results at impressive speeds, making them ideal for businesses that rely on bulk printing, such as packaging companies, sign manufacturers, and commercial printers. This article delves into the reasons why UV roll printers are perfect for long-run printing and explores the factors that make them superior for high-volume production.

1. Consistent Quality and Precision

One of the most significant advantages of UV roll printers for long-run printing is their ability to maintain consistent print quality throughout the entire run. Traditional printers often face issues with color variations, ink smudging, or print defects as the printing job progresses. However, UV roll printers use ultraviolet (UV) light to cure the ink immediately after printing, which results in a faster drying time and a more stable final product. This curing process ensures that the ink adheres properly to the material, providing rich, vibrant colors and crisp, sharp images without any fading or smudging. The result is a highly uniform print quality that remains constant from the first to the last print, an essential feature for long-run projects.

Additionally, UV roll printers can print on a variety of materials, including non-porous surfaces such as plastics, metals, and glass. This versatility further adds to the printer's appeal, allowing businesses to work with different substrates without compromising the print's quality. Whether it’s creating custom labels, packaging designs, or large banners, UV roll printers ensure that every piece meets the same high standards, no matter the material used.

2. High-Speed Printing for Increased Efficiency

Another reason UV roll printers are ideal for long-run printing is their speed. These printers are designed to handle large volumes of printing with impressive turnaround times, making them a powerful asset for any high-volume printing operation. The efficiency of UV roll printers allows businesses to complete bulk orders more quickly and meet tight deadlines without sacrificing quality.

UV roll printers also feature automatic registration and alignment systems that reduce the chances of human error during production. This automation streamlines the process, minimizes downtime, and enhances operational efficiency. This is particularly valuable for industries that require large quantities of identical products or prints in a short period of time, such as packaging and commercial printing. Whether you're printing rolls of labels or large-format graphics, UV roll printers can deliver a fast and reliable production process, ensuring high throughput and quick turnarounds on long-run jobs.

In addition, UV curing technology enables printers to produce immediate results. Unlike traditional printing methods that require drying time, UV ink dries instantly, allowing the printed materials to be processed, packaged, or shipped right away. This speed and convenience contribute to a faster overall production cycle and can significantly improve a company’s ability to meet customer demands for quick deliveries.

3. Cost-Effectiveness in the Long Run

For any business looking to increase their bottom line, cost efficiency is key. UV roll printers can contribute to significant cost savings in long-run printing due to their minimal need for maintenance and the reduced cost of consumables. Traditional inkjet or offset printing methods can require frequent ink replacements and maintenance, which can be expensive and time-consuming. In contrast, UV inks are highly durable, and since the ink is cured immediately, it requires fewer touch-ups or adjustments during the run. This leads to lower operational costs over time.

Furthermore, the ability to print on various types of materials with minimal adjustments makes UV roll printers more versatile than their traditional counterparts. Businesses can avoid investing in separate equipment for different materials, as a single UV roll printer can handle various substrates with ease. This flexibility translates into fewer machine setups and a reduced need for multiple print runs, all of which help to lower production costs in the long term.

Conclusion

In summary, UV roll printers are ideal for long-run printing due to their ability to consistently produce high-quality results, their fast printing speeds, and their cost-effectiveness. They offer unmatched precision, ensuring that each print meets the same high standards from the beginning to the end of the run. Additionally, the speed and automation of UV roll printers make them perfect for meeting tight deadlines and managing high-volume jobs efficiently. Finally, their ability to work with a wide range of materials while keeping operational costs low makes them a valuable investment for businesses looking to optimize their printing operations. UV roll printers are undoubtedly an excellent choice for businesses in need of a reliable and high-performance solution for long-run printing needs.

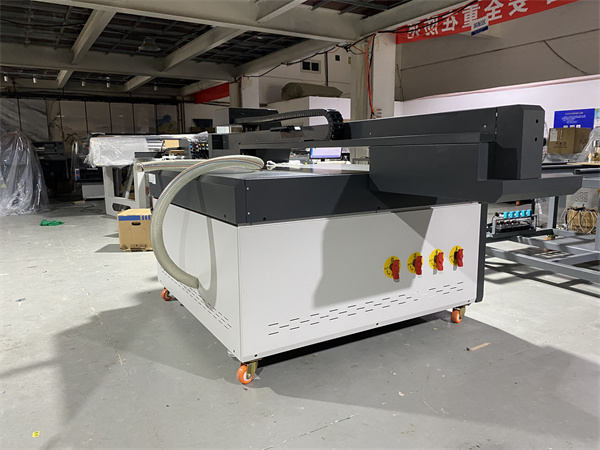

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies