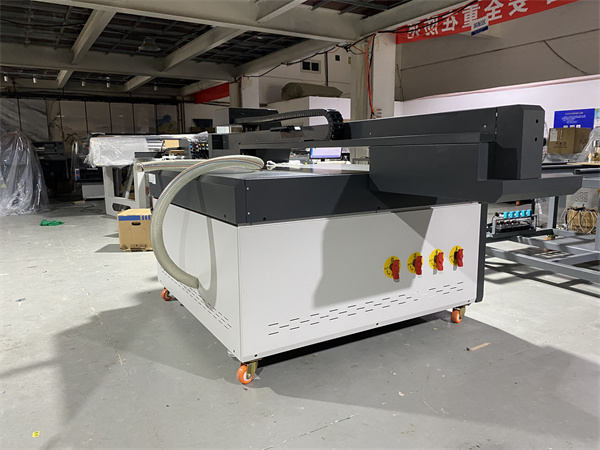

uv machine--Ultraviolet Curing Machine: An Industrial Marvel

Unveiling the Power and Applications of UV Machines

UV machines, also known as ultraviolet curing machines, have become an integral part of various industries due to their efficiency and effectiveness. These machines use ultraviolet light to cure or dry inks, coatings, adhesives, and other materials rapidly. The process involves exposing the material to UV light, which initiates a chemical reaction that causes the material to harden or dry almost instantly.

How UV Machines Work

The core of a UV machine is the UV lamp. These lamps emit ultraviolet light in a specific wavelength range, typically between 200 to 400 nanometers. When the material containing photo - initiators is exposed to this UV light, the photo - initiators absorb the energy and break down into free radicals. These free radicals then react with the monomers and oligomers in the material, causing them to polymerize and form a solid, cured layer.

For example, in the printing industry, UV - curable inks are used. When the printed material passes under the UV machine, the inks dry immediately. This allows for faster production speeds as there is no need to wait for the inks to air - dry. A printing company that switched from traditional inks to UV - curable inks and a UV machine saw a significant increase in their daily production volume. They could print and finish more jobs in a shorter time, leading to higher customer satisfaction and increased revenue.

Applications of UV Machines

One of the most common applications of UV machines is in the coating industry. UV - curable coatings are used on a variety of surfaces, including wood, metal, and plastic. These coatings provide a hard, durable finish that is resistant to scratches, chemicals, and wear. For instance, in the furniture manufacturing industry, UV - cured coatings are applied to wooden furniture. The UV machine cures the coating quickly, and the furniture can be handled and packaged soon after the coating process. This reduces the production time and storage space required for the furniture to dry.

Another important application is in the electronics industry. UV adhesives are used to bond components together. The UV machine can cure these adhesives precisely, ensuring a strong and reliable bond. In the production of smartphones, UV adhesives are used to attach the display to the phone's frame. The use of a UV machine allows for a quick and accurate bonding process, which is crucial for the high - volume production of these devices.

UV machines also find applications in the medical field. They are used to sterilize medical equipment by using UV - C light, which has germicidal properties. Hospitals use UV sterilization machines to disinfect surgical instruments, reducing the risk of infections in patients.

In conclusion, UV machines offer numerous benefits in terms of speed, quality, and efficiency across different industries. Their ability to cure materials rapidly and precisely makes them an essential tool in modern manufacturing and processing.

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Local Production, Global Reach: UV Flatbeds Empowering Small Business Exporters

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

Inventory-Free Business Models: On-Demand UV Printing for Just-in-Time Production

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

From Mass Production to Mass Customization: How UV Flatbeds are Reshaping Manufacturing

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies

Emerging Market Solutions: Affordable UV Flatbeds for Developing Economies