The Future of Printing: UV Flatbed Printer

Exploring the Advancements and Impact of UV Flatbed Printers in the Future of Print Production

In recent years, the printing industry has undergone remarkable transformations with the introduction of cutting-edge technologies. Among these, UV flatbed printing has gained significant attention due to its versatility, speed, and sustainability. This article delves into the future of printing, focusing specifically on UV flatbed printers, which are rapidly changing the landscape of print production across various industries.

What is a UV Flatbed Printer?

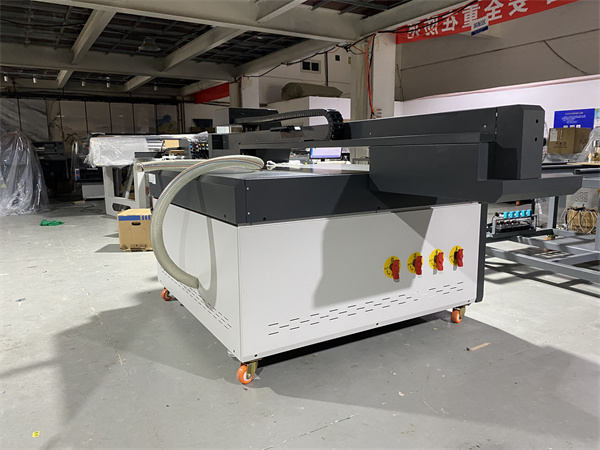

UV flatbed printers are advanced machines designed to print directly onto a variety of rigid and flexible materials, such as glass, wood, metal, acrylic, and more. Unlike traditional printers, which rely on paper as the primary medium, UV flatbed printers use ultraviolet (UV) light to cure inks immediately after they are printed onto a surface. This instant curing process allows for higher precision, more vibrant colors, and greater durability compared to conventional inkjet or laser printing methods.

The "flatbed" aspect refers to the flat surface on which the materials are placed, providing a stable and consistent printing platform. This unique characteristic makes UV flatbed printers ideal for large-format printing, especially when dealing with non-standard substrates or custom shapes. The technology enables businesses to print not only high-quality graphics but also intricate details that would be difficult to achieve using traditional printing methods.

The Advantages of UV Flatbed Printing

UV flatbed printers offer numerous benefits that are driving their popularity across various industries. One of the key advantages is their ability to print on almost any surface, from promotional products to architectural elements. This opens up endless possibilities for designers and manufacturers looking to create customized, one-of-a-kind products. Whether it's creating a personalized gift, a branded item, or an industrial component, the UV flatbed printer offers the flexibility to print on materials that were previously not compatible with traditional printing methods.

Another significant advantage is the eco-friendly nature of UV printing. The inks used in UV flatbed printers are UV-curable, meaning they do not emit harmful volatile organic compounds (VOCs) into the environment, unlike traditional solvent-based inks. This makes UV flatbed printing a more sustainable option for businesses looking to reduce their carbon footprint and adhere to environmental regulations. Additionally, the instant curing of UV inks reduces energy consumption compared to other printing methods, contributing to energy efficiency in production processes.

Furthermore, UV flatbed printers deliver exceptional print quality. The high resolution and wide color gamut achievable with UV technology ensure that printed images and graphics are sharp, vibrant, and long-lasting. UV inks also provide excellent adhesion to a wide range of substrates, reducing the risk of fading or scratching over time. This makes UV flatbed printing especially ideal for outdoor signage, retail displays, and other products exposed to wear and tear.

Future Trends in UV Flatbed Printing

Looking ahead, UV flatbed printing technology is poised to evolve even further, with several exciting trends on the horizon. One of the most notable advancements is the integration of automation and AI into the printing process. Smart printers, which can adjust settings based on the material type and thickness, are becoming more common, making the process faster and more efficient. AI-driven software can also optimize print designs, color profiles, and even predict maintenance needs, improving productivity and minimizing downtime for businesses.

Another promising trend is the increasing use of UV printers in the packaging industry. With the growing demand for custom packaging, UV flatbed printers offer a cost-effective and high-quality solution for brands looking to create personalized packaging for their products. The ability to print directly onto a wide variety of materials, including corrugated cardboard, is revolutionizing how packaging is produced. This trend is expected to grow as more brands prioritize unique, eye-catching packaging as a way to stand out in the competitive market.

Additionally, advancements in the development of UV inks are likely to enhance the durability and versatility of UV flatbed printers. Innovations in ink formulations will make it possible to print on an even broader range of materials, including textiles, ceramics, and flexible substrates. This expansion of material compatibility will further cement the role of UV flatbed printing in industries like interior design, fashion, and automotive manufacturing, where customized solutions are in high demand.

Conclusion: The Bright Future of UV Flatbed Printing

As we move into the future, UV flatbed printing is set to become an even more integral part of the printing landscape. With its ability to print on diverse materials, deliver superior quality, and offer sustainable solutions, UV flatbed printers are shaping the next generation of print technology. The integration of automation, AI, and innovations in ink development will continue to drive the growth and expansion of this technology. Businesses that adopt UV flatbed printing are well-positioned to stay ahead of the curve, offering their customers customized, high-quality products that meet the demands of an ever-evolving market.

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Digital Workflow Optimization: From Design to Finished Product in Record Time

Digital Workflow Optimization: From Design to Finished Product in Record Time