UV Printers: The Perfect Choice for Printing on Leather

Discover the benefits of UV printing technology for leather products and its superior print quality

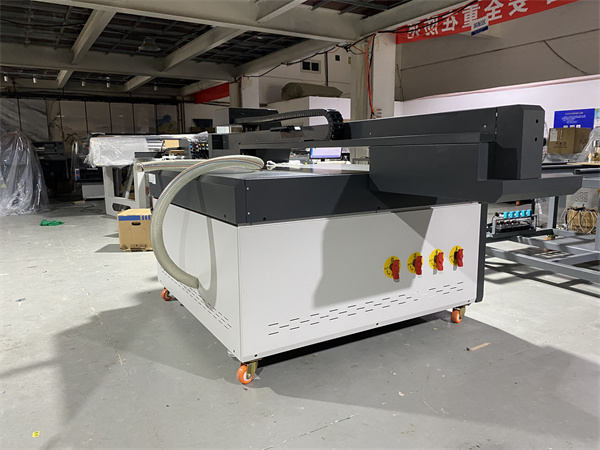

In recent years, UV printing technology has gained significant popularity due to its versatility and high-quality output. When it comes to printing on leather, UV printers stand out as an excellent choice. The unique capabilities of UV printers make them ideal for creating vibrant, durable, and precise prints on leather surfaces. Whether for fashion, accessories, or upholstery, UV printers provide unmatched advantages that traditional printing methods struggle to match. This article explores why UV printers are the perfect choice for printing on leather, highlighting their benefits, features, and practical applications.

Advantages of UV Printing on Leather

UV printers use ultraviolet light to cure ink as it is printed, resulting in fast drying times and vibrant colors. This technology offers a variety of benefits, particularly when applied to leather. One of the primary advantages of UV printing on leather is its ability to produce high-quality prints with exceptional color accuracy and detail. Unlike other methods, UV printers do not rely on heat, which can damage sensitive leather surfaces. This ensures that the leather retains its natural texture and appearance while still achieving stunning, sharp images.

Another significant benefit of UV printing is its durability. UV-cured inks are resistant to fading, scratching, and water damage, which is particularly important for leather products that are exposed to frequent use and wear. Whether you're printing on leather bags, shoes, or furniture, the UV print will remain vibrant and intact for a longer period compared to traditional printing methods. Additionally, UV printing allows for printing on both rigid and flexible leather materials, making it versatile for various types of leather goods.

Applications of UV Printing in the Leather Industry

UV printers are increasingly being used in the leather industry for a wide range of applications. One of the most common uses is for personalized leather products. Customization is a major trend in fashion, with consumers seeking unique designs on their leather goods. UV printers allow designers and manufacturers to print intricate patterns, logos, images, and even photographs directly onto leather, offering a high degree of creativity and flexibility. Whether it’s for creating branded items, custom footwear, or bespoke leather bags, UV printers offer the precision and quality needed to meet customer demands.

Moreover, UV printing is also ideal for creating promotional leather products, such as wallets, keychains, and other accessories. These items often feature logos, brand names, or catchy slogans that require clear, high-definition printing. UV printers deliver crisp text and vibrant graphics on leather surfaces, making them perfect for promotional campaigns, giveaways, or corporate gifts. Additionally, UV printing enables full-color printing, so complex designs with multiple colors can be reproduced accurately on leather.

UV printing technology also plays a role in the production of leather upholstery for furniture. Custom designs and patterns can be printed on leather seats, armchairs, and other upholstered items, allowing for unique interior decor options. This application is particularly valuable in industries where branding and personalization are important, such as luxury furniture or high-end automotive interiors.

Furthermore, UV printing technology is highly efficient in mass production scenarios. With the ability to print multiple leather pieces simultaneously, manufacturers can achieve faster turnaround times, which is beneficial for both small businesses and large-scale operations. The high-speed capabilities of UV printers also minimize downtime and help optimize production workflows, reducing costs while maintaining quality.

Conclusion: Why UV Printers Are the Best Choice for Leather Printing

UV printing technology has revolutionized the way leather products are designed and manufactured. Its ability to produce high-quality, durable, and vibrant prints makes it the perfect choice for printing on leather. Whether you're creating custom leather goods, promotional items, or personalized upholstery, UV printers offer unmatched flexibility and precision. The advantages of UV printing, such as fast drying times, resistance to wear and tear, and the ability to print on various leather surfaces, make it an invaluable tool in the leather industry.

In conclusion, the versatility, speed, and exceptional print quality offered by UV printers make them an ideal solution for anyone involved in leather printing. As the demand for customized and high-quality leather products continues to rise, UV printers will remain at the forefront of the industry, offering businesses and consumers alike the opportunity to create unique, long-lasting leather goods that stand out in the market.

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Digital Workflow Optimization: From Design to Finished Product in Record Time

Digital Workflow Optimization: From Design to Finished Product in Record Time