A Beginner's Guide to UV Wood Printing

Learn the basics of UV printing on wood, the process, and techniques for stunning results

UV wood printing has become a popular method for achieving high-quality, long-lasting prints on wooden surfaces. Whether you are a hobbyist or a professional looking to explore new printing techniques, this guide will walk you through the basics of UV wood printing. With its ability to produce vibrant colors, detailed graphics, and durable finishes, UV printing is an excellent choice for anyone looking to create custom designs on wood.

What is UV Wood Printing?

UV wood printing refers to a type of digital printing where ultraviolet (UV) light is used to cure (dry) the ink as it is applied to a wooden surface. This method uses special UV-sensitive inks that are cured instantly by UV light, allowing the ink to bond tightly with the wood surface. Unlike traditional printing methods, UV printing offers the advantage of printing directly on uneven surfaces like wood, enabling high-resolution graphics and vibrant colors that last longer.

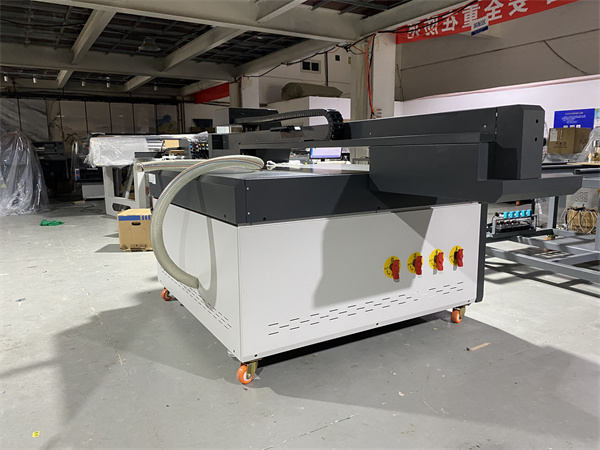

UV wood printing works by using UV printers equipped with specialized inks and print heads. These printers print the design directly onto the wood using ultraviolet light to immediately cure the ink. As a result, the ink adheres to the wood instantly without the need for drying time, making it an efficient and effective printing method. This printing technique is versatile, allowing you to create a wide variety of designs on different wood types, from softwoods to hardwoods.

The Process of UV Wood Printing

The process of UV wood printing can be broken down into several key steps. Each step plays a crucial role in ensuring the print quality and longevity of the design. Below is a simplified version of the typical process:

Step 1: Preparing the Wood Surface – Before printing, the wood surface needs to be clean and smooth. Sand the wood to ensure it is free from dust, oils, or any other contaminants that could interfere with the ink’s adhesion. This step is crucial for ensuring a flawless print that will last.

Step 2: Loading the Design into the Printer – Once the wood is prepped, the next step is to load the design into the UV printer. You can use design software to create or edit your artwork. The file is then transferred to the printer, which will begin printing the design directly onto the wood surface.

Step 3: Printing the Design – The UV printer sprays tiny droplets of ink onto the wood, where the ultraviolet light immediately cures the ink. This results in vibrant, crisp prints that are durable and resistant to fading. You can adjust the printer settings to control the ink density, resolution, and other print characteristics.

Step 4: Curing and Finishing – After the print is completed, the ink is fully cured, creating a smooth, glossy finish. Depending on the desired effect, additional coats of varnish or protective coatings may be applied to enhance durability and provide a high-quality finish.

Benefits of UV Wood Printing

UV wood printing offers several distinct advantages over traditional printing methods. Some of the key benefits include:

- Durability: UV prints are highly durable and resistant to scratches, fading, and wear, making them ideal for long-term use in furniture, signage, or home décor.

- Vibrant Colors: UV printing produces bright, vivid colors with exceptional detail and accuracy. The ink bonds effectively to the wood, ensuring that your designs pop.

- Eco-Friendly: Since UV printing doesn’t require solvents or excessive energy to dry the ink, it is considered a more environmentally friendly option compared to traditional methods.

- Versatility: UV printing can be used on various types of wood, including raw, painted, or varnished wood. It also allows for printing on different textures, enabling creative and custom applications.

- Fast Production: The UV curing process is incredibly fast, allowing for quick turnaround times. The prints are instantly dry and ready for handling or shipping, increasing productivity and efficiency.

Considerations for Successful UV Wood Printing

While UV wood printing offers many advantages, there are also a few considerations to keep in mind to ensure optimal results:

- Wood Type: Different types of wood absorb ink differently. Softer woods like pine may absorb ink more quickly, while hardwoods such as oak may require more precise printer settings to get the desired result.

- Printer Maintenance: Regular maintenance of your UV printer is essential for consistent performance. Clean the print heads and ensure the UV lamps are functioning correctly to maintain print quality.

- Design Preparation: The resolution and file quality of your design are crucial for achieving a sharp, professional-looking print. Ensure your design files are in high resolution to prevent pixelation and ensure fine details are printed accurately.

UV wood printing opens up a world of possibilities for creating custom wood products with stunning designs. Whether you're working on a small-scale project or a large production run, this technique allows for exceptional print quality and durability. With the proper tools, preparation, and attention to detail, you can create beautiful, long-lasting wood prints that will stand the test of time.

Conclusion

UV wood printing is an innovative and versatile method that allows you to produce high-quality, durable prints on a variety of wooden surfaces. It is an ideal solution for creating custom designs for furniture, signage, artwork, and other wood-based projects. By understanding the process, benefits, and considerations, beginners can confidently venture into the world of UV printing and achieve professional results. With the right equipment and techniques, UV wood printing is a rewarding and creative way to transform ordinary wood into personalized works of art.

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Digital Workflow Optimization: From Design to Finished Product in Record Time

Digital Workflow Optimization: From Design to Finished Product in Record Time