How to Get the Most Out of Your UV Printer

Unlocking the Full Potential of Your UV Printing System

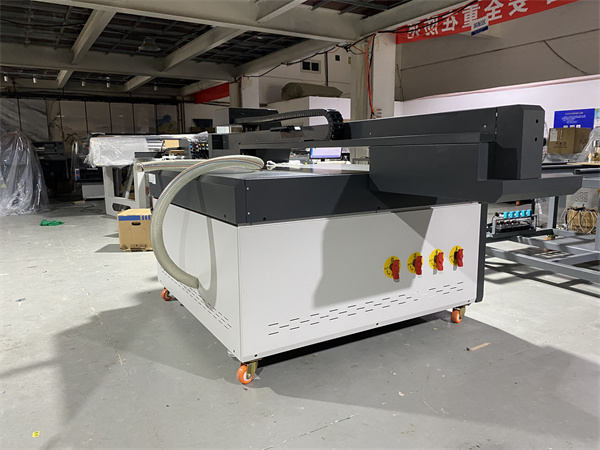

UV printers are powerful tools that can help businesses and creative professionals produce high-quality prints on a variety of materials. Whether you're printing on paper, plastic, glass, or even metal, a UV printer can deliver sharp, vibrant results. However, to truly get the most out of your UV printer, it's important to understand how to optimize its performance and ensure you’re using it effectively. This guide provides you with essential tips on how to maximize the capabilities of your UV printer and achieve optimal results.

1. Choose the Right Materials for Your UV Printer

One of the most significant factors in getting the best output from your UV printer is selecting the correct materials. UV printing can be done on a variety of substrates, including rigid and flexible materials such as acrylic, wood, glass, metal, textiles, and more. However, not all materials are created equal when it comes to UV printing.

Before printing, it's crucial to test the material to ensure that it works well with UV ink. Some surfaces may require a primer or coating for better adhesion, while others may produce poor results if not treated properly. Make sure you check the manufacturer's guidelines for your UV printer and follow their recommendations regarding material compatibility.

For example, printing on plastic can sometimes present challenges in terms of ink adhesion. In such cases, using a surface treatment such as a corona treatment or applying a special UV primer will improve the final print quality. Similarly, printing on glass and metal often requires specific inks designed for those surfaces to prevent smudging or fading.

2. Regular Maintenance and Calibration

To maintain high print quality and prevent unexpected downtime, regular maintenance and calibration are essential. Like any other printing technology, UV printers require periodic cleaning and adjustments to ensure consistent results. Keep the print heads, ink lines, and other moving parts clean to avoid clogged nozzles, which can lead to poor print quality or even printer damage.

Calibrating the printer is also a key part of maintenance. Calibration ensures that the print heads are aligned properly, the colors are accurate, and the print resolution is optimal. This process might need to be done at regular intervals, especially when you notice color shifts or when the print quality starts to degrade.

It’s also important to monitor the condition of the ink. UV inks can dry out if not used properly, leading to nozzle blockages. To avoid this, you should make sure your UV printer uses fresh ink, and store it in proper conditions to extend its shelf life. Some printers even have automated cleaning systems that can help reduce the manual labor involved in maintaining the printer, but regular inspection and manual cleaning are still recommended.

3. Use the Correct Printing Settings

The settings on your UV printer can drastically impact the quality of the output. By adjusting the resolution, curing speed, and ink usage, you can optimize the print quality for each specific material and project. Higher resolution settings are typically used for detailed designs or fine text, while lower resolutions can be used for larger, less detailed prints to save time and ink.

One key setting is the curing speed. The UV light used to cure the ink should be set correctly to ensure that the ink adheres to the material without over-curing or under-curing. Over-curing can lead to ink chipping or cracking, while under-curing can cause the ink to smudge or peel off the surface. Adjusting the curing speed according to the material being printed on and the type of ink used will yield better results.

Furthermore, be mindful of the print mode you select. Some UV printers allow you to adjust settings like the number of passes and the ink laydown thickness. Adjusting these settings appropriately based on your material and design can help you avoid wasting ink or compromising the detail in your prints.

4. Take Advantage of Design Software Features

To truly unlock the power of your UV printer, integrating the right design software into your workflow can make a huge difference. Software tools allow you to create complex designs that take full advantage of your printer’s capabilities. Many UV printers are compatible with professional design programs like Adobe Illustrator, CorelDRAW, or specialized RIP (Raster Image Processor) software.

Using these software tools, you can optimize your designs to take full advantage of the UV printer’s unique capabilities. For example, you can design prints with layers or use spot UV effects to create texture, gloss, or high-contrast details. These effects can give your prints a distinctive look that adds value to the final product.

Additionally, design software often allows for pre-press checks and adjustments, ensuring that the files are optimized for your printer before the printing process begins. It’s always a good practice to preview your designs and check for any potential issues that may arise during printing, such as color misalignment or resolution loss.

5. Proper Handling of Finished Prints

Once your prints are finished, proper handling is key to maintaining the integrity of the output. UV prints can be delicate in the first few hours after printing, especially when they are newly cured. Be cautious when handling prints on materials like acrylic or glass, as they can be prone to scratches or smudging if not handled properly.

Make sure to allow ample time for the print to fully cure before handling or packaging. Even though UV ink dries quickly under UV light, it can take a little longer for the ink to cure completely, especially in the case of thicker prints or multi-layered designs.

Additionally, storing printed items in a safe, dust-free environment will help preserve their quality. For printed items that need to be stored for an extended period, use protective covers or packaging to avoid physical damage or exposure to UV light, which could degrade the print over time.

Conclusion

Getting the most out of your UV printer involves a combination of choosing the right materials, maintaining your printer, adjusting settings, utilizing design software, and handling the finished prints properly. By following these steps, you can maximize your printer’s potential and produce stunning, high-quality results on a variety of substrates. Regular care and attention to detail will ensure that your UV printing system continues to perform at its best, allowing you to create durable, professional-grade prints for any project.

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

The Silent Revolution: Noise-Reduced UV Flatbeds Transforming Workspace Environments

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Multi-Material Mastery: UV Flatbeds Printing on Composite and Hybrid Surfaces

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Rapid Curing Science: The Physics Behind Instant UV Polymerization

Digital Workflow Optimization: From Design to Finished Product in Record Time

Digital Workflow Optimization: From Design to Finished Product in Record Time